OVERVIEW

With its exceptional facilities and expertise, Orient MetaCorp Pvt. Ltd. has established a niche for itself throughout time. We have a significant advantage in handling changing customer needs while upholding the highest standards of quality since all of our forging press lines are extremely flexible.

GET IN TOUCH

Our cutting operations are powered by state-of-the-art Circular Saw machines designed for high-accuracy billet preparation. Unlike conventional cutting methods, our circular saw systems ensure:

Precision at the cutting stage directly impacts forging quality. By maintaining strict dimensional control and uniform billet geometry, we ensure optimal material flow and reduced forging defects in subsequent processes.

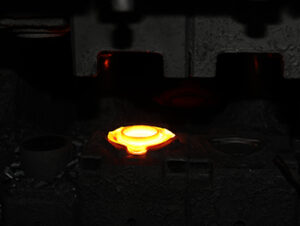

Our forging facility is equipped with high-performance Mechanical Presses and Screw Presses ranging from 150 tons up to 1000 tons, enabling us to manufacture components across a wide range of sizes and complexities.

This versatile press capacity allows us to:

The combination of controlled billet preparation and high-tonnage forging equipment ensures structural integrity, repeatability, and reliability — even for critical automotive and industrial applications.

Every stage — from cutting to forging — is engineered for precision, durability, and efficiency. Our modern infrastructure, coupled with experienced operators and process control systems, ensures:

We don’t just forge components — we engineer strength into every part.

Overview

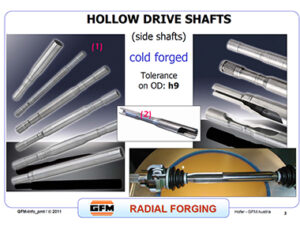

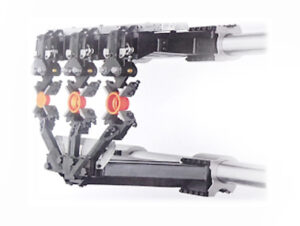

Four radially oscillating tools are used in the state-of-the-art incremental forming technique known as GFM radial forging technology. This novel technique offers remarkable design versatility, allowing metallic materials to be formed in cold, warm, and hot environments. It easily produces intricate hollow outlines in a single, effective process using mandrels.

Key Features

- Advanced Robotic Automation: A programmable process ensures precision and consistency with minimal operator intervention.

- High-Speed Production: Capable of up to 1,200 oscillations per minute, making it ideal for high-volume production runs.

- Versatile Applications: Perfect for producing complex, high-precision forged components across various industries.

- Unmatched Accuracy and Reliability: Built for manufacturers aiming to elevate their forging operations.